MAY 14, 2024 • By Matthew Tierney

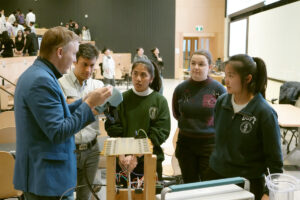

In April, ECE’s fourth-year undergraduate students showcased their team-based projects at the 2024 Capstone Design Fair, held over three nights in the Myhal Centre.

Capstone is a yearlong project design course (ECE496) that asks the students to develop an initial concept into a working prototype. This year, coordinator Professor Bruno Korst says the department incorporated industry reporting processes to better mirror what students can expect in the workplace.

“I conducted multiple interviews with former students and hired two project administrators who currently work in industry. They all said written reports have given way to brief meetings on deliverables — what’s been done, what’s up next — and then everyone moves on.

“So we simplified the documentation for the students and had stand-up meetings over the two semesters. It set an industry pace, which meant that the students had to pick it up. You can see it in the results this year, which to my eye are more focused.”

“Developing a working engineering prototype requires a combination of teamwork, dedication and the application of a variety of ECE skills acquired from our classrooms and labs,” says ECE Chair Professor Deepa Kundur. “Each year, it’s inspiring to see how much the students have learned and their pride in their projects. The design fair is one of the highlights in our academic year.”

This Capstone team project highlight is part 2 of 3.

Read part 1: Improving the battery system for neurological implants

Read part 3: Helping students find their classrooms with an indoor campus visualization app

Part 2: Lenscrafters

“You go into a store, you select frames that you like, you pay $500 or so,” says Omar Farag (Year 4 CompE), “then wait a couple of weeks. When you go to pick up the glasses, you don’t like them.”

This is the problem that he and his teammates Tawseef Hanif and Jessica He (both Year 4, CompE) look to solve with their project, LensCrafters (with a nod to the retailer by that name).

The team created a graphical user interface (GUI) that uses the specifics of your prescription to show you a 3D representation of exactly how your chosen frames look with the lenses inserted. The 3D viewer allows you to change the angle, zoom in, see the lenses within the frames or alone.

The look of the lenses is the result of a complex process that takes into account the myriad corrective options and lens-making procedures for different vision problems.

For example, one would need a spherical lens to correct nearsightedness or farsightedness — concave or convex, respectively — while a cylindrical lens corrects astigmatism, which is a condition where the eye has multiple focus points. The higher the refractive index, the thinner the lens, but a higher index requires different, more expensive materials. It’s a choice the consumer must weigh.

“Our app allows you to choose a number that represents a cheaper option,” says He. “But say you’ve chosen thin, metal frames. After seeing the 3D illustration, you might consider paying for higher index lenses because you don’t like how the thicker lenses stick out past the edge of the frames.”

The app has other helpful features, such as an augmented “try-on” tool, which places a virtual pair of glasses on the user’s face. Also included is the weight of the frames plus lenses.

“Sometimes if your glasses are too heavy, you get wear marks on the bridge of your nose,” says Farag. “It’s important info to have.”

The most challenging part of the project was calculating the geometry to know how to cut the lens for accurate representation.

“Prescriptions are given in powers of magnitude, such as 1.0 or 1.25,” says Hanif. “We had to convert that number into a radius of the sphere that we’d cut out of the lens. And while optics can give you a good approximation, the optimization of the optics for lens manufacturers are industry secrets.”

Given more time, Hanif says they’d would have liked to allow for more complex prescriptions, such as bifocals and progressives, as well as a better process to combine spherical and cylindrical-powered lenses, which complicates the magnitude.

When asked what advice he’d give upcoming students, Hanif says, “Whatever time you estimate for your project, it’ll take double or triple that.”