April 16, 2020

A U of T Engineering team, led by Professor Willy Wong (ECE/BME) has created a simple, scalable solution to remotely monitor the vital signs of COVID-19 patients. This technology could help preserve vital personal protective equipment (PPE) for health-care workers.

Currently, hospitals use a fingertip probe to monitor the respiratory status in COVID-19 patients. This probe outputs to bedside monitors that must be read by nursing staff every four hours or more.

But some patients experience a rapid deterioration in respiratory status that requires even more frequent monitoring, putting additional pressure on staff.

“And because health-care workers need to put on and remove PPEs before interacting with patients, this requires considerable time and use of resources,” says Wong.

Two weeks ago, clinicians from Mount Sinai Hospital in Toronto reached out to U of T Engineering to see if researchers could come up with a solution — quickly — that would help clinicians monitor respiratory probes both continuously, and remotely.

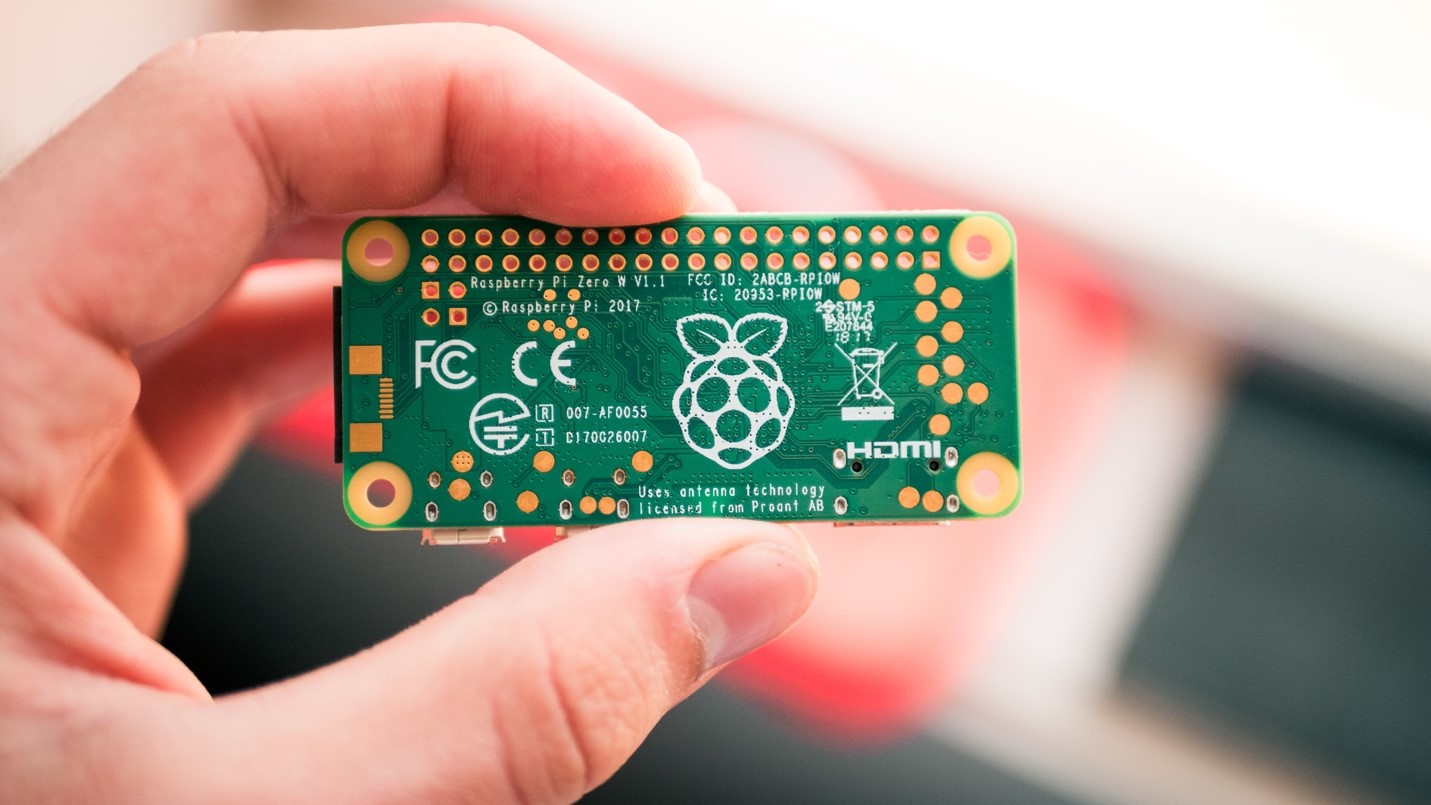

In just three days Wong and his students PhD candidates Bill Shi (BME PhD/MD), Yan Li (ECE) and Brian Wang (ChemE) put together a proof of concept using a Raspberry Pi, a simple and affordable single-board computer. Just a few days later, they were ready to deploy their prototype in a hospital setting.

“The challenge was to find something that was small, affordable and that we could put together very quickly,” says Wong. “I don’t have specific expertise in the area, but as a researcher working in the biomedical engineering group here in ECE, I have experience in the development of medical devices and thought I might be able to help.”

The Raspberry Pi is a mini-computer that’s about the size of a credit card. When attached to the fingertip probe, it can continuously read data and communicate it via WiFi to a server that Wong’s team deployed.

“The most challenging part has been decoding the data the monitors provide because there are a number of different manufacturers of these probes and each one has its own format,” says Wong. “The students were working day and night to decode the data outputted from these devices.”

One key aspect is the portability of the solution that Wong and his students came up with. “In a hospital setting we don’t really have the luxury of putting a laptop with wires going everywhere next to each patient,” says Wong. “The Raspberry Pi is something that our undergraduates use a lot in their fourth-year design projects, it just connects by cable to the oxygen saturation probe and then another cable to an outlet in the wall for power: that’s it.”

The new setup enables doctors and nurses to read a patient’s oxygen saturation levels every few minutes or less from the nursing station. The team is working with Mount Sinai and Toronto General to determine the feasibility and demand for these devices. Their solution is rapidly deployable and scalable to other venues, including emergency hospitals.

“When you put together a solution quickly there are a few things you need to be mindful of, including concerns like patient privacy and data security, as well as usability of equipment by the front-line medical staff,” says Wong. “But it would be great if they didn’t need to use them, as it would mean they aren’t being overwhelmed by a surge of COVID-19 patients.”

Wong says it has been a valuable experience for his students.

“This was a quintessentially electrical and computer engineering problem,” says Wong. “I saw the opportunity to help and this group of really smart and hardworking students rose to the challenge.”

More information:

Jessica MacInnis

External Relations Manager

The Edward S. Rogers Sr. Department of Electrical & Computer Engineering

416-978-7997; jessica.macinnis@utoronto.ca