MAY 13, 2024 • By Matthew Tierney

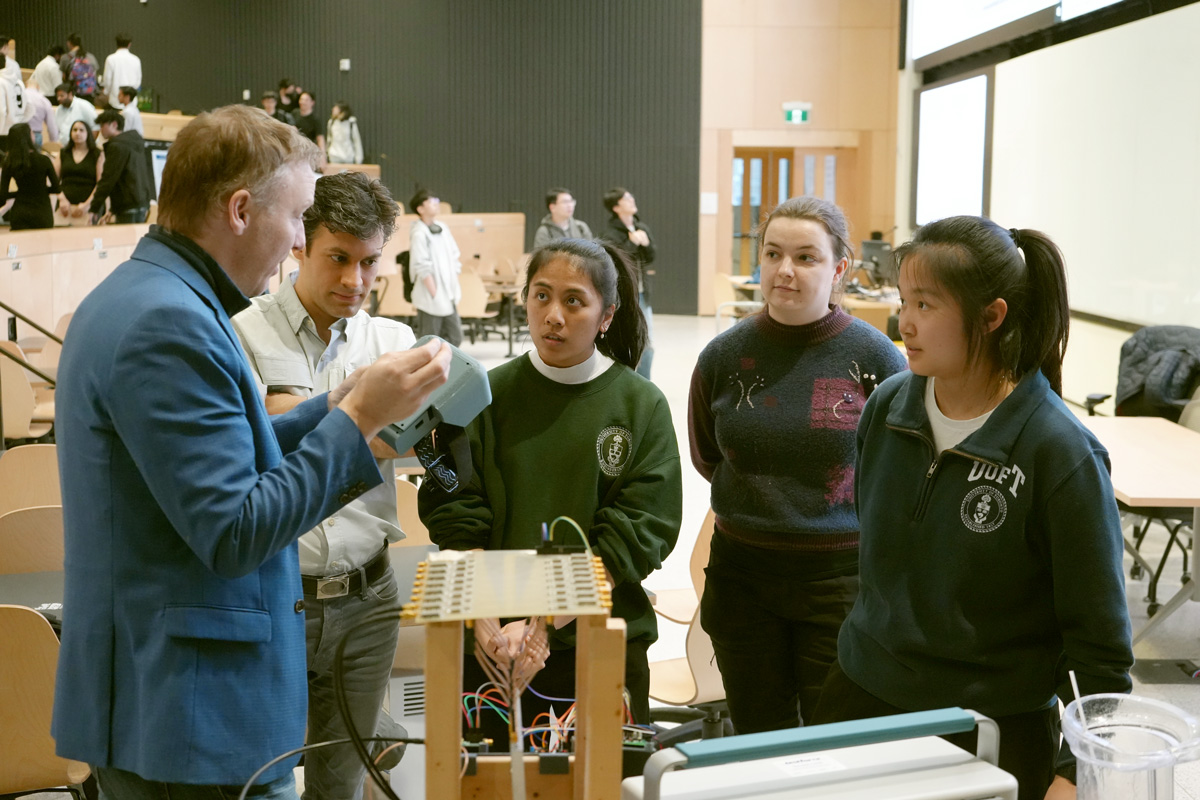

In April, ECE’s fourth-year undergraduate students showcased their team-based projects at the 2024 Capstone Design Fair, held over three nights in the Myhal Centre.

Capstone is a yearlong project design course (ECE496) that asks the students to develop an initial concept into a working prototype. This year, coordinator Professor Bruno Korst says the department incorporated industry reporting processes to better mirror what students can expect in the workplace.

“I conducted multiple interviews with former students and hired two project administrators who currently work in industry. They all said written reports have given way to brief meetings on deliverables — what’s been done, what’s up next — and then everyone moves on.

“So we simplified the documentation for the students and had stand-up meetings over the two semesters. It set an industry pace, which meant that the students had to pick it up. You can see it in the results this year, which to my eye are more focused.”

“Developing a working engineering prototype requires a combination of teamwork, dedication and the application of a variety of ECE skills acquired from our classrooms and labs,” says ECE Chair Professor Deepa Kundur. “Each year, it’s inspiring to see how much the students have learned and their pride in their projects. The design fair is one of the highlights in our academic year.”

This Capstone team project highlight is part 1 of 3.

Read part 2: Guiding consumers with an app that accurately shows prescriptive lens in frames

Read part 3: Helping students find their classrooms with an indoor campus visualization app

Part 1: Wireless Power Transfer to Multiple Implantable Neurological Devices

Deep-brain stimulation is a therapeutic procedure that can help with the symptoms of Parkinson’s disease and other neurological disorders. It involves implants in the brain, which deliver pulses of electric current to specific areas.

The team of Selena Liu, Aurora Nowicki and Kimberley Orna (all Year 4 ElecE) developed a way to improve the battery system that powers those implants. Their Capstone project was mentored by Mohammad Abdolrazzaghi (ECE PhD candidate), a member of ECE professor Roman Genov’s lab, and it also received support from ECE professor George Eleftheriades. The project received the John W. Senders Award for Imaginative Design.

“The state of the technology right now requires patients to have a battery pack implanted beneath their collarbone, with implanted electrodes and wires that run through their neck,” says Nowicki. “They need to get this battery replaced every five or seven years. It’s very invasive.”

But what if one could power the implants wirelessly?

“When people think of wireless charging, they often picture the inductive power transfer of an electric toothbrush or phone,” says Nowicki.

“But that only works when the distance is less than five centimetres,” Liu says, “and it’s not precise enough for our purposes. We used what’s called far-field or power beaming, which is how your cell phone communicates with a cell tower, in the radio frequency.”

The team’s solution incorporated an antenna array worn around the patient’s head.

“We send power that’s specifically conditioned — by that, I mean we shift the phase and change the amplitude — to six different antennas on a headband,” says Orna. “That enables the antennas to beam power into the head at a very precise location.”

The power is controlled by a graphical user interface (GUI) they built using Python. It offers two modes of operation to the clinician: automatic and manual. Automatic mode adjusts the six different waveforms into an interference pattern that targets the x-y-z location of the implant as inputted in the GUI. Manual mode gives clinicians some therapeutic options by allowing them to manipulate the power or temporal delay of each waveform.

“A real advantage for our solution versus electrodes, which don’t move once they’re implanted, is when the patient has multiple devices in the brain. The clinician would be able to control an exact power transfer to the x-y-z location of each one,” says Liu.

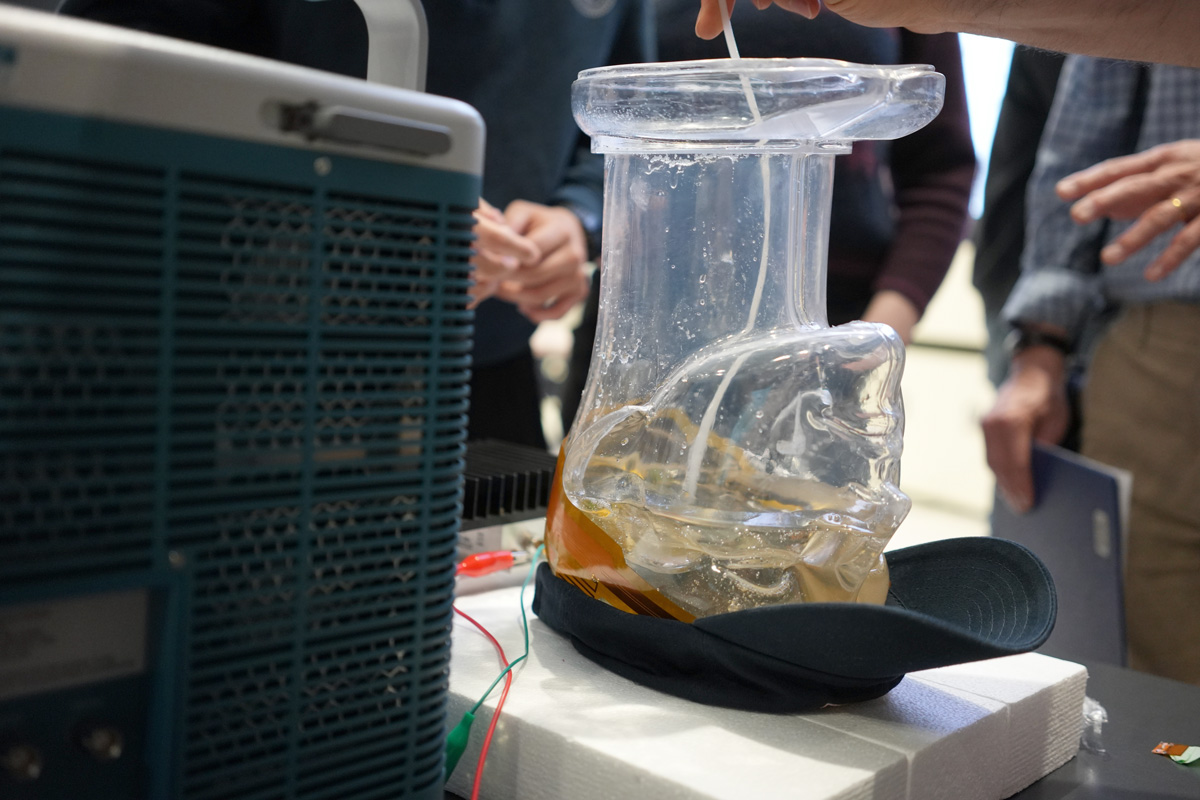

To demo their proof of concept, they successfully lit up LED lights as stand-in implants in a model head filled with solution that simulates cerebrospinal fluid.

The team miniaturized the integrated system — the microcontroller, the radio frequency synthesizer, signal generator, and amplifier — into a printed circuit board that fit a 3D-printed housing case about the size of a phone. The case is small enough to either be strapped to the headband or worn as a fanny pack.

Even though Capstone is now over, their ambitions for the project are not.

“Our hope to get this PCB manufactured so that we can test at the frequency of 950 MHz, which is a frequency that is safe for sending power into the brain, at high efficiency, that minimizes any heat losses,” says Liu.